چگونه یک راکتور شیشه ای شیمیایی را به درستی تمیز و نگهداری کنیم

2026-01-16

.gtr-container-k9p2q7 {

font-family: Verdana, Helvetica, "Times New Roman", Arial, sans-serif;

color: #333;

line-height: 1.6;

padding: 16px;

max-width: 100%;

box-sizing: border-box;

}

.gtr-container-k9p2q7 .gtr-heading-main {

font-size: 18px;

font-weight: bold;

margin-bottom: 16px;

color: #0056b3;

text-align: left;

}

.gtr-container-k9p2q7 .gtr-heading-sub {

font-size: 18px;

font-weight: bold;

margin-top: 24px;

margin-bottom: 12px;

color: #0056b3;

text-align: left;

}

.gtr-container-k9p2q7 p {

font-size: 14px;

margin-bottom: 12px;

text-align: left !important;

word-break: normal;

overflow-wrap: normal;

}

.gtr-container-k9p2q7 strong {

font-weight: bold;

}

.gtr-container-k9p2q7 ul {

margin: 0 0 12px 20px;

padding: 0;

list-style: none !important;

}

.gtr-container-k9p2q7 ul li {

font-size: 14px;

margin-bottom: 8px;

position: relative;

padding-left: 18px;

text-align: left !important;

list-style: none !important;

}

.gtr-container-k9p2q7 ul li::before {

content: "•" !important;

color: #0056b3;

font-size: 18px;

position: absolute !important;

left: 0 !important;

top: -2px;

}

.gtr-container-k9p2q7 ol {

margin: 0 0 12px 20px;

padding: 0;

list-style: none !important;

counter-reset: list-item;

}

.gtr-container-k9p2q7 ol li {

font-size: 14px;

margin-bottom: 8px;

position: relative;

padding-left: 25px;

text-align: left !important;

list-style: none !important;

}

.gtr-container-k9p2q7 ol li::before {

content: counter(list-item) "." !important;

color: #0056b3;

font-weight: bold;

position: absolute !important;

left: 0 !important;

top: 0;

width: 20px;

text-align: right;

}

.gtr-container-k9p2q7 .gtr-table-wrapper {

width: 100%;

overflow-x: auto;

margin-bottom: 20px;

}

.gtr-container-k9p2q7 table {

width: 100%;

border-collapse: collapse !important;

border-spacing: 0 !important;

margin: 0 !important;

font-size: 14px;

min-width: 500px;

}

.gtr-container-k9p2q7 th,

.gtr-container-k9p2q7 td {

border: 1px solid #ccc !important;

padding: 10px !important;

text-align: left !important;

vertical-align: top !important;

word-break: normal;

overflow-wrap: normal;

}

.gtr-container-k9p2q7 th {

background-color: #f0f0f0;

font-weight: bold !important;

color: #333;

}

.gtr-container-k9p2q7 tbody tr:nth-child(even) {

background-color: #f9f9f9;

}

@media (min-width: 768px) {

.gtr-container-k9p2q7 {

padding: 24px 32px;

}

.gtr-container-k9p2q7 .gtr-heading-main {

font-size: 24px;

margin-bottom: 20px;

}

.gtr-container-k9p2q7 .gtr-heading-sub {

font-size: 20px;

margin-top: 30px;

margin-bottom: 15px;

}

.gtr-container-k9p2q7 table {

min-width: auto;

}

.gtr-container-k9p2q7 .gtr-table-wrapper {

overflow-x: visible;

}

}

نحوه تمیز کردن و نگهداری صحیح از راکتور شیشه ای شیمیایی

مقدمه

تمیز کردن و نگهداری صحیح برای اطمینان از عملکرد، ایمنی و قابلیت اطمینان طولانی مدت یک راکتور شیشه ای شیمیایی ضروری است. تجمع باقیمانده، جابجایی نادرست یا نگهداری بی توجهانه می تواند منجر به آلودگی، کاهش راندمان و حتی خرابی تجهیزات شود.

در این مقاله، ما یک راهنمای عملی در مورد نحوه تمیز کردن و نگهداری صحیح از یک راکتور شیشه ای شیمیایی ارائه می دهیم، که به آزمایشگاه ها و تأسیسات شیمیایی کمک می کند تا عمر مفید را افزایش داده و کیفیت واکنش را حفظ کنند.

چرا تمیز کردن و نگهداری حیاتی است

راکتورهای شیشه ای شیمیایی اغلب برای واکنش های متعدد شامل مواد شیمیایی مختلف استفاده می شوند. بدون تمیز کردن مناسب:

ممکن است آلودگی متقابل رخ دهد

نتایج واکنش ممکن است ناسازگار شوند

سطوح شیشه ای ممکن است با گذشت زمان تخریب شوند

نگهداری منظم نه تنها از تجهیزات محافظت می کند، بلکه نتایج آزمایشی دقیق و تکرارپذیر را نیز تضمین می کند.

روش های تمیز کردن روزانه

پس از هر دسته واکنش، تمیز کردن اولیه باید انجام شود:

باقیمانده های واکنش را تخلیه کنیدتمام مواد واکنش را بردارید و طبق دستورالعمل های ایمنی دور بریزید.

شستشوی اولیهراکتور را با یک حلال مناسب یا آب دیونیزه بشویید تا باقیمانده های سست از بین بروند.

تمیز کردن ملایماز برس های نرم یا پارچه های غیر ساینده استفاده کنید. از ابزارهای تیز که می توانند سطح شیشه را خراش دهند، خودداری کنید.

شستشوی نهایی و خشک کردنراکتور را کاملاً بشویید و اجازه دهید به طور طبیعی یا با هوای تمیز خشک شود.

از استفاده از پاک کننده های ساینده خودداری کنید، زیرا ممکن است به سطح شیشه بوروسیلیکات آسیب برسانند.

تمیز کردن عمیق برای باقیمانده های سرسخت

برای واکنش هایی که رسوبات سنگین بر جای می گذارند:

از مواد تمیز کننده شیمیایی سازگار که برای شیشه بوروسیلیکات توصیه می شود استفاده کنید

اجازه دهید محلول تمیز کننده قبل از هم زدن ملایم خیس بخورد

اطمینان حاصل کنید که تمام مهر و موم ها و اتصالات پس از آن کاملاً شسته شوند

همیشه سازگاری شیمیایی را تأیید کنید تا از خوردگی شیشه یا آسیب به مهر و موم جلوگیری شود.

نگهداری از مهر و موم ها و واشرها

مهر و موم ها و واشرها اجزای حیاتی یک راکتور شیشه ای شیمیایی هستند. بازرسی منظم برای موارد زیر ضروری است:

تشخیص سایش یا تغییر شکل

جلوگیری از نشت در حین عملکرد خلاء یا فشار

حفظ یکپارچگی سیستم

مهر و موم های فرسوده را سریعاً تعویض کنید تا از خطرات ایمنی و خرابی عملیاتی جلوگیری شود.

سیستم همزن و اجزای مکانیکی

شافت همزن، موتور و یاتاقان ها را به طور منظم بررسی کنید:

چرخش روان بدون سر و صدای غیرعادی را تضمین کنید

تراز مناسب را تأیید کنید

در صورت نیاز سازنده، اجزا را روغن کاری کنید

نگهداری صحیح از قطعات مکانیکی، راندمان اختلاط را بهبود می بخشد و عمر تجهیزات را طولانی می کند.

بررسی سیستم کنترل خلاء و دما

اگر راکتور تحت خلاء کار می کند:

اتصالات خلاء را از نظر نشتی بررسی کنید

پایداری فشار را در حین کار تأیید کنید

برای سیستم های کنترل دما:

پمپ های گردش خون را بررسی کنید

شیلنگ ها و اتصالات را بازرسی کنید

خواندن دقیق دما را تأیید کنید

بررسی های معمول به جلوگیری از خرابی های غیرمنتظره در طول واکنش های بحرانی کمک می کند.

بهترین روش های ذخیره سازی و جابجایی

هنگامی که استفاده نمی شود:

راکتور را در یک محیط تمیز و خشک نگهداری کنید

از اجزای شیشه ای در برابر ضربه محافظت کنید

از تغییرات ناگهانی دما خودداری کنید

ذخیره سازی مناسب، خطر آسیب تصادفی را به میزان قابل توجهی کاهش می دهد.

مزایای نگهداری منظم

مزیت

تاثیر

عمر مفید طولانی تر

کاهش هزینه های جایگزینی

نتایج واکنش پایدار

بهبود قابلیت تکرار

ایمنی بهبود یافته

کاهش خطر نشت یا شکستگی

کاهش زمان خرابی

افزایش راندمان آزمایشگاه

نتیجه

تمیز کردن و نگهداری یک راکتور شیشه ای شیمیایی پیچیده نیست، اما به ثبات و توجه به جزئیات نیاز دارد. مراقبت مناسب از سرمایه گذاری شما محافظت می کند، عملکرد ایمن را تضمین می کند و نتایج واکنش با کیفیت بالا را حفظ می کند.

اگر به راهنمایی فنی، قطعات یدکی یا پشتیبانی حرفه ای برای سیستم راکتور شیشه ای شیمیایی خود نیاز دارید، کار با یک تولید کننده قابل اعتماد تفاوت ایجاد می کند.

مشاهده بیشتر

چگونه یک راکتور شیشه ای شیمیایی به کنترل دقیق دما دست می یابد؟

2026-01-16

.gtr-container-7f8a9b {

font-family: Verdana, Helvetica, "Times New Roman", Arial, sans-serif;

color: #333;

padding: 15px;

max-width: 100%;

box-sizing: border-box;

}

.gtr-container-7f8a9b .gtr-title {

font-size: 18px;

font-weight: bold;

margin-bottom: 20px;

line-height: 1.3;

text-align: left;

}

.gtr-container-7f8a9b .gtr-subtitle {

font-size: 18px;

font-weight: bold;

margin-top: 30px;

margin-bottom: 15px;

line-height: 1.4;

text-align: left;

}

.gtr-container-7f8a9b p {

font-size: 14px;

line-height: 1.6;

margin-bottom: 15px;

text-align: left !important;

}

.gtr-container-7f8a9b hr {

border: none;

border-top: 1px solid #eee;

margin: 30px 0;

}

.gtr-container-7f8a9b ul {

margin: 0 0 15px 0;

padding: 0;

list-style: none;

}

.gtr-container-7f8a9b li {

list-style: none !important;

position: relative;

padding-left: 25px;

margin-bottom: 8px;

font-size: 14px;

line-height: 1.6;

text-align: left;

}

.gtr-container-7f8a9b ul li::before {

content: "•" !important;

position: absolute !important;

left: 0 !important;

color: #0056b3;

font-size: 1.2em;

line-height: 1;

top: 0;

}

.gtr-container-7f8a9b .gtr-table-wrapper {

overflow-x: auto;

margin-bottom: 20px;

}

.gtr-container-7f8a9b table {

width: 100%;

border-collapse: collapse;

border-spacing: 0;

margin-bottom: 0;

font-size: 14px;

line-height: 1.6;

}

.gtr-container-7f8a9b th,

.gtr-container-7f8a9b td {

border: 1px solid #ccc !important;

padding: 12px 10px;

text-align: left;

vertical-align: top;

word-break: normal;

overflow-wrap: normal;

}

.gtr-container-7f8a9b th {

font-weight: bold;

color: #333;

}

.gtr-container-7f8a9b strong {

font-weight: bold;

}

@media (min-width: 768px) {

.gtr-container-7f8a9b {

padding: 30px;

max-width: 960px;

margin: 0 auto;

}

.gtr-container-7f8a9b table {

display: table;

}

}

چگونه یک رآکتور شیشه ای شیمیایی می تواند درجه حرارت را به دقت کنترل کند؟

مقدمه

کنترل درجه حرارت یکی از مهمترین پارامترهای واکنش های شیمیایی است. حتی نوسانات کوچک می تواند بر سرعت واکنش، خلوص محصول، بهره وری و ایمنی تاثیر بگذارد.این به ویژه در تحقیق و توسعه داروسازی صدق می کند، سنتز شیمیایی دقیق و آزمایش در مقیاس آزمایشگاهی.

Aراکتور شیشۀ شیمیاییبه طور خاص طراحی شده است تا کنترل دمای پایدار، دقیق و قابل تکرار را فراهم کند. در این مقاله، ما توضیح می دهیمچگونه راکتورهای شیشه ای شیمیایی کنترل دقیق دما را به دست می آورند، و چرا این توانایی برای پردازش شیمیایی مدرن ضروری است.

چرا کنترل دما در واکنش های شیمیایی اهمیت دارد؟

بسیاری از واکنش های شیمیایی به تغییرات دمایی بسیار حساس هستند. کنترل ضعیف دمای ممکن است منجر به:

واکنش های ناقص

محصولات جانبی ناخواسته

تولید واکنش کاهش یافته

خطرات ایمنی مانند واکنش های ناگهانی

به همین دلیل، آزمایشگاه ها و کارخانه های آزمایشی نیاز به سیستم های راکتور دارند که می توانند دمای ثابت را در طول کل فرآیند واکنش حفظ کنند.

نقش طرح ژاکت

هسته ی کنترل دقیق دمای در یک راکتور شیشه ای شیمیایی درساختاري با پوشش.

یک راکتور شیشه ای پوشیده از:

یکرگ داخلیجایی که واکنش شیمیایی رخ می دهد

یکژاکت بیرونیکه رسانه های گرمایشی یا خنک کننده را گردش می کند

محیط گرمایشی مانند آب، روغن سیلیکون یا گلیکول به طور مساوی در اطراف ظرف داخلی جریان دارد و گرما را به طور غیرمستقیم از طریق دیواره شیشه بوروسیلیکات منتقل می کند.این روش گرمایش غیرمستقیم تضمین توزیع یکسانی دمای بدون تماس مستقیم بین منبع حرارت و مواد واکنش می کند..

واحدهای کنترل دما و سیستم های گردش

رآکتورهای شیشه ای شیمیایی به طور معمول به واحدهای کنترل دمای خارجی متصل می شوند. این سیستم ها به اپراتورها اجازه می دهند:

تنظیم دماهای هدف دقیق

تنظیم نرخ گرمایش و خنک سازی

حفظ شرایط پایدار در طول زمان واکنش طولانی

پمپ های گردش خون با کیفیت بالا جریان ثابت محیط گرمایش را تضمین می کنند، گرادیان درجه حرارت را به حداقل می رسانند و از گرم شدن بیش از حد یا خنک شدن محلی جلوگیری می کنند.

مزایای شیشه بوروسیلیکات برای انتقال گرما

شیشه بوروسیلیکات نقش کلیدی در ثبات دمایی دارد. خواص آن عبارتند از:

مقاومت عالی در برابر ضربه های حرارتی

عملکرد پایدار در طیف گسترده ای از دما

ویژگی های انتقال گرما ثابت

این ویژگی ها اجازه می دهد تا راکتورهای شیشه ای شیمیایی بدون از دست دادن ایمنی یا عملکرد، هر دو فرآیند گرم کردن و خنک کردن سریع را مدیریت کنند.

اهمیت مخلوط کردن

کنترل دقیق دما تنها در مورد گرم کردن یا خنک کردن نیست بلکه به مخلوط موثر نیز بستگی دارد. راکتورهای شیشه ای شیمیایی با سیستم های مخلوط مکانیکی مجهز هستند که:

حرارت را به طور مساوی در سراسر مخلوط واکنش توزیع کنید

از نقاط داغ یا مناطق سرد جلوگیری کنید

بهبود بهره وری و ثبات واکنش

تحرک مناسب تضمین می کند که همه واکنش دهنده ها شرایط حرارتی یکسان را تجربه کنند، که برای نتایج قابل تکرار بسیار مهم است.

عملکرد خلاء و کنترل دمای

بسیاری از رآکتورهای شیشۀ شیمیایی ازعملکرد خلاء، که کنترل درجه حرارت را بیشتر بهبود می بخشد.

نقطه جوش محلول ها کاهش می یابد

واکنش ها می توانند در دمای پایین تر رخ دهند

تخریب حرارتی مواد حساس به حداقل می رسد

این قابلیت به ویژه در کاربردهای داروسازی و شیمیایی خوب ارزشمند است.

چالش ها و راه حل های رایج کنترل دمای

چالش

چگونه راکتورهای شیشه ای آن را حل می کنند

گرمایش نامنظم

طراحی ژاکت تضمین انتقال گرمای یکنواخت

افزایش دما

کنترل کننده های خارجی تنظیم دقیق را فراهم می کنند

عدم ثبات واکنش

محیط حرارتی ثابت کنترل را بهبود می بخشد

خطرات ایمنی

گرمایش غیرمستقیم خطر گرم شدن بیش از حد را کاهش می دهد

نتیجه گیری

یک راکتور شیشه ای شیمیایی از طریق ساختار پوشش داده شده، سیستم های گردش خون خارجی، شیشه بوروسیلیکات با کیفیت بالا و مکانیسم های موثر مخلوط کردن، کنترل دقیق دمای را به دست می آورد.با هم، این ویژگی ها یک محیط واکنش پایدار و قابل پیش بینی ایجاد می کنند.

برای آزمایشگاه ها و کارخانه های آزمایشی که دقت و ایمنی ضروری است، سرمایه گذاری در یکراکتور شیشه ای شیمیایی با عملکرد بالاتصمیم هوشمندانه ای بود.

مشاهده بیشتر

راکتور شیشه شیمیایی در مقابل راکتور فولاد ضد زنگ: تفاوت های کلیدی توضیح داده شده است

2026-01-16

.gtr-container-x7y3z1 {

font-family: Verdana, Helvetica, "Times New Roman", Arial, sans-serif;

color: #333;

line-height: 1.6;

padding: 15px;

max-width: 100%;

box-sizing: border-box;

}

.gtr-container-x7y3z1__main-title {

font-size: 18px;

font-weight: bold;

margin-bottom: 20px;

color: #1a1a1a;

text-align: left;

}

.gtr-container-x7y3z1__section-title {

font-size: 16px;

font-weight: bold;

margin-top: 25px;

margin-bottom: 15px;

color: #2a2a2a;

text-align: left;

}

.gtr-container-x7y3z1 p {

font-size: 14px;

margin-bottom: 15px;

text-align: left !important;

color: #444;

}

.gtr-container-x7y3z1 strong {

font-weight: bold;

color: #0056b3; /* A subtle blue for emphasis, common in industrial UIs */

}

.gtr-container-x7y3z1__separator {

border: none;

border-top: 1px solid #e0e0e0;

margin: 30px 0;

}

@media (min-width: 768px) {

.gtr-container-x7y3z1 {

padding: 25px;

}

.gtr-container-x7y3z1__main-title {

font-size: 20px;

margin-bottom: 30px;

}

.gtr-container-x7y3z1__section-title {

font-size: 18px;

margin-top: 35px;

margin-bottom: 20px;

}

.gtr-container-x7y3z1 p {

font-size: 14px;

margin-bottom: 18px;

}

.gtr-container-x7y3z1__separator {

margin: 40px 0;

}

}

راکتور شیشه شیمیایی در مقابل راکتور فولاد ضد زنگ: تفاوت های کلیدی توضیح داده شده است

مقدمه

انتخاب مواد مناسب راکتور یک تصمیم حیاتی برای پردازش شیمیایی، تحقیقات آزمایشگاهی و تولید در مقیاس آزمایشی است.رآکتورهای شیشه ای شیمیاییوراکتورهای فولاد ضد زنگهرکدام مزایا، محدودیت ها و موارد استفاده ایده آل خود را دارند.

این مقاله یک مقایسه دقیق برای کمک به شما در تعیینکدام نوع راکتور مناسب ترین کاربرد شما است؟.

ترکیب مواد و مقاومت شیمیایی

رآکتورهای شیشه ی شیمیایی از شیشه ی بوروسیلیکات بالا ساخته شده اند که مقاومت بالاتری نسبت به اسید ها، قلیات و محلول های آلی دارند.ممکن است با مواد شیمیایی خاص واکنش نشان دهد یا نیاز به پوشش های ویژه داشته باشد..

برای فرآیندهای بسیار خوردنی یا حساس به خلوص، راکتورهای شیشه ای اغلب انتخاب امن تر هستند.

دید واکنش

یکی از مهم ترین تفاوت ها شفافیت است. راکتورهای شیشه ای امکان نظارت بصری کامل بر روند واکنش را فراهم می کنند و به اپراتورها امکان می دهند مشکلات مانند فوم، بارندگی،یا مخلوط کردن ناقص.

رآکتورهای فولاد ضد زنگ، که نامروری هستند، به سنسورها و ابزارها متکی هستند که ممکن است تمام جزئیات فرآیند را در طول تحقیق و توسعه ضبط نکنند.

کنترل دما و انتقال گرما

راکتورهای شیشه ای جاکت شده انتقال گرمای یکنواخت را از طریق گرمایش غیرمستقیم فراهم می کنند. راکتورهای فولاد ضد زنگ به طور کلی تحمل فشار بیشتری را ارائه می دهند اما اگر به درستی طراحی نشده باشند ممکن است نقاط داغ ایجاد کنند.

برای واکنش های حساس به دما، راکتورهای شیشه ای عملکرد حرارتی کنترل شده و قابل پیش بینی تری را ارائه می دهند.

ملاحظات ایمنی

رآکتورهای شیشه ای برای کاربردهای با فشار پایین تا متوسط طراحی شده اند و برای عملیات خلاء ایده آل هستند.که آنها را برای تولید صنعتی مناسب می کند.

در محیط های آزمایشگاهی و مقیاس آزمایشی، شرایط کنترل شده راکتورهای شیشه ای اغلب منجر به عملیات ایمن تر می شود.

تمیز کردن و نگهداری

رآکتورهای شیشه ای تمیز کردن و بازرسی آنها آسان تر است و زمان توقف بین آزمایش ها را کاهش می دهد. رآکتورهای فولاد ضد زنگ ممکن است نیاز به روش های تمیز کردن گسترده تری داشته باشند، به ویژه هنگام تغییر محصولات.

برای تاسیساتی که تغییرات مکرر دسته را انجام می دهند، راکتورهای شیشه ای مزایای عملیاتی روشنی را ارائه می دهند.

هزینه و سفارشی سازی

راکتورهای شیشه ای شیمیایی به طور کلی هزینه های اولیه کمتری برای کاربردهای آزمایشگاهی و مقیاس آزمایشی دارند. همچنین سفارشی سازی آنها با پورت های اضافی، تهویه کننده ها یا لوازم جانبی آسان تر است.

راکتورهای فولاد ضد زنگ شامل هزینه های تولید و سفارشی سازی بالاتر هستند اما برای تولید مستمر در مقیاس بزرگ مناسب تر هستند.

نتیجه گیری

هر دو رآکتور شیشه ای شیمیایی و رآکتورهای فولاد ضد زنگ نقش مهمی در پردازش شیمیایی دارند.انعطاف پذیریرآکتورهای فولاد ضد زنگ برای تولید صنعتی با فشار بالا و حجم بزرگ مناسب تر هستند.

درک نیازهای فرآیند شما کلید انتخاب درست است.

مشاهده بیشتر

چرا راکتورهای شیشه ای شیمیایی به طور گسترده ای در تحقیقات و توسعه داروسازی استفاده می شوند؟

2026-01-16

.gtr-container-pharma-xyz789 {

font-family: Verdana, Helvetica, "Times New Roman", Arial, sans-serif;

color: #333;

line-height: 1.6;

padding: 20px;

max-width: 100%;

box-sizing: border-box;

}

.gtr-container-pharma-xyz789 .gtr-pharma-title-main {

font-size: 18px;

font-weight: bold;

margin-bottom: 20px;

text-align: left;

color: #0056b3;

}

.gtr-container-pharma-xyz789 .gtr-pharma-title-section {

font-size: 16px;

font-weight: bold;

margin-top: 25px;

margin-bottom: 15px;

text-align: left;

color: #0056b3;

}

.gtr-container-pharma-xyz789 .gtr-pharma-title-subsection {

font-size: 14px;

font-weight: bold;

margin-top: 20px;

margin-bottom: 10px;

text-align: left;

color: #0056b3;

}

.gtr-container-pharma-xyz789 p {

font-size: 14px;

margin-bottom: 15px;

text-align: left !important;

word-break: normal;

overflow-wrap: normal;

}

.gtr-container-pharma-xyz789 strong {

font-weight: bold;

}

.gtr-container-pharma-xyz789 .gtr-separator {

border-bottom: 1px solid #eee;

margin: 25px 0;

}

.gtr-container-pharma-xyz789 ul {

list-style: none !important;

padding-left: 20px;

margin-bottom: 15px;

}

.gtr-container-pharma-xyz789 ul li {

position: relative;

padding-left: 15px;

margin-bottom: 8px;

font-size: 14px;

text-align: left;

list-style: none !important;

}

.gtr-container-pharma-xyz789 ul li::before {

content: "•" !important;

position: absolute !important;

left: 0 !important;

color: #0056b3;

font-size: 16px;

line-height: 1;

}

.gtr-container-pharma-xyz789 ol {

list-style: none !important;

padding-left: 25px;

margin-bottom: 15px;

}

.gtr-container-pharma-xyz789 ol li {

position: relative;

padding-left: 20px;

margin-bottom: 8px;

font-size: 14px;

text-align: left;

display: list-item;

list-style: none !important;

}

.gtr-container-pharma-xyz789 ol li::before {

content: counter(list-item) "." !important;

position: absolute !important;

left: 0 !important;

color: #0056b3;

font-weight: bold;

width: 18px;

text-align: right;

}

@media (min-width: 768px) {

.gtr-container-pharma-xyz789 {

padding: 30px 50px;

max-width: 960px;

margin: 0 auto;

}

.gtr-container-pharma-xyz789 .gtr-pharma-title-main {

font-size: 22px;

margin-bottom: 30px;

}

.gtr-container-pharma-xyz789 .gtr-pharma-title-section {

font-size: 18px;

margin-top: 35px;

margin-bottom: 20px;

}

.gtr-container-pharma-xyz789 .gtr-pharma-title-subsection {

font-size: 16px;

margin-top: 25px;

margin-bottom: 12px;

}

.gtr-container-pharma-xyz789 p {

margin-bottom: 18px;

}

.gtr-container-pharma-xyz789 ul {

padding-left: 25px;

}

.gtr-container-pharma-xyz789 ul li {

padding-left: 20px;

}

.gtr-container-pharma-xyz789 ol {

padding-left: 30px;

}

.gtr-container-pharma-xyz789 ol li {

padding-left: 25px;

}

}

چرا راکتورهای شیشه ای شیمیایی به طور گسترده ای در تحقیقات و توسعه داروسازی استفاده می شوند؟

مقدمه

تحقیقات و توسعه داروسازی تجهیزات مورد نیاز است که دقت، ایمنی و قابل تکرار بودن را ارائه می دهد.حتی انحرافات جزئی در شرایط واکنش می تواند منجر به نتایج ناسازگار شود.. به همین دلیلرآکتورهای شیشه ای شیمیاییبه طور گسترده ای در آزمایشگاه های تحقیق و توسعه داروسازی در سراسر جهان استفاده می شود.

در این مقاله، ما در موردچرا رآکتورهای شیشی شیمیایی در تحقیقات داروسازی ضروری هستند؟، و اینکه چگونه از فرآیندهای توسعه با کیفیت بالا، سازگار و کارآمد پشتیبانی می کنند.

نقش راکتورهای شیشی شیمیایی در تحقیق و توسعه داروسازی

تحقیق و توسعه دارویی شامل چندین مرحله واکنش، از جمله سنتز، تصفیه، کریستالیزه شدن و بازیابی محلول است.راکتورهای شیشه ای شیمیایی محیط کنترل شده ای را فراهم می کنند که در آن محققان می توانند این فرآیندهای را به دقت مدیریت کنند.

ساختار شفاف و پیکربندی قابل سازگاری آنها را برای هر دو تنظیمات تولید آزمایشی و در مقیاس کوچک ایده آل می کند.

مزایای کلیدی برای کاربردهای دارویی

سازگاری شیمیایی بالا

واکنش های داروسازی اغلب شامل حلال ها و عامل های تهاجمی است. شیشه بوروسیلیکات مقاومت عالی در برابر خوردگی را ارائه می دهد، از آلودگی جلوگیری می کند و پاکیزه محصول را تضمین می کند.

درجه حرارت دقیق و کنترل فرآیند

بسیاری از واکنش های دارویی به درجه حرارت حساس هستند. راکتورهای شیشه ای جاکت به محققان اجازه می دهند شرایط حرارتی پایدار را حفظ کنند و تولید مجدد واکنش و بهره را بهبود بخشند.

نظارت بصری بر واکنش ها

برخلاف راکتورهای فلزی، راکتورهای شیشه ای امکان دید کامل را فراهم می کنند. محققان می توانند به راحتی تغییرات فاز، رفتار کریستالیزاسیون و پیشرفت واکنش را بدون قطع روند مشاهده کنند.

ظرفیت خلاء و تقطیر

راکتورهای شیشه ای شیمیایی از عملکرد خلاء پشتیبانی می کنند و باعث می شوند تقطیر دمای پایین و بازیابی محلول برای فرمولاسیون و تصفیه دارویی حیاتی باشد.

انطباق و ایمنی آزمایشگاه

ایمنی در آزمایشگاه های داروسازی اولویت اصلی است. راکتورهای شیشه ای شیمیایی با:

سیستم های گرمایش غیرمستقیم

کار با فشار و خلاء کنترل شده

مواد ساختمانی پایدار و غیرفعال

این ویژگی ها به آزمایشگاه ها کمک می کنند تا با استانداردهای ایمنی داخلی و انتظارات قانونی مطابقت داشته باشند.

انعطاف پذیری برای تحقیق و توسعه و مقیاس آزمایشی

راکتورهای شیشه ای شیمیایی در ظرفیت های مختلف از واحدهای کوچک آزمایشگاهی تا سیستم های مقیاس آزمایشی در دسترس هستند. طرح های ماژولار امکان سفارشی سازی آسان را فراهم می کند و آنها را برای:

بهینه سازی فرآیند

آزمایش مقیاس بالا

تولید دسته های کوچک API

این انعطاف پذیری باعث کاهش تخفیف تجهیزات و هزینه های سرمایه گذاری کلی می شود.

رآکتورهای شیشه ای در مقابل رآکتورهای فولاد ضد زنگ در تحقیق و توسعه دارویی

در حالی که راکتورهای فولاد ضد زنگ در تولید در مقیاس بزرگ رایج هستند، راکتورهای شیشه ای مزایای کلیدی را در تحقیق و توسعه ارائه می دهند:

دید بهتر

تمیز کردن آسان تر بین دسته ها

خطر کمتری از آلودگی متقابل

تنظیم سریع تر برای تغییرات تجربی

برای محیط های متمرکز بر تحقیق، راکتورهای شیشه ای همچنان انتخاب مورد علاقه هستند.

نتیجه گیری

رآکتورهای شیشه ای شیمیایی نقش مهمی در تحقیق و توسعه داروسازی با ارائه دقت، ایمنی و سازگاری دارند.و کنترل درجه حرارت عالی به محققان کمک می کند تا نتایج قابل اعتماد و قابل تکرار را به دست آورند.

اگر آزمایشگاه داروسازی شما در حال برنامه ریزی برای ارتقاء یا گسترش سیستم های راکتور خود است،رآکتور شیشه ای شیمیایی با کیفیت بالامی تواند به طور قابل توجهی هم بهره وری و هم ایمنی را بهبود بخشد.

مشاهده بیشتر

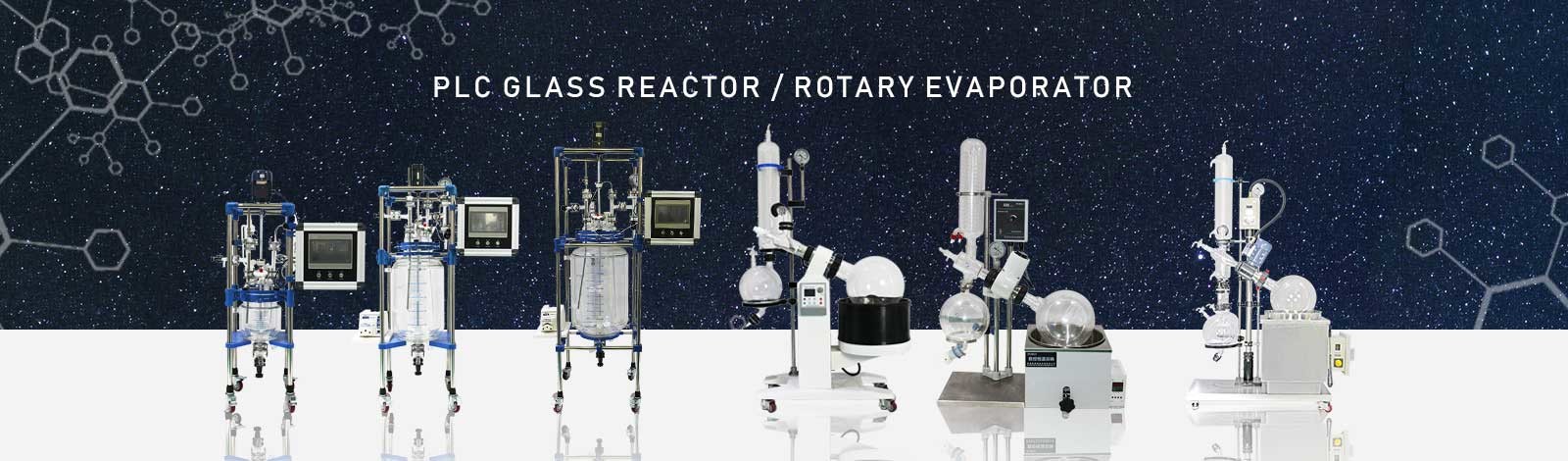

یک راکتور شیشه ای چیست و چگونه کار می کند؟

2026-01-16

.gtr-container-p9q8r7 {

font-family: Verdana, Helvetica, "Times New Roman", Arial, sans-serif;

color: #333;

line-height: 1.6;

padding: 16px;

max-width: 100%;

box-sizing: border-box;

}

.gtr-container-p9q8r7 * {

box-sizing: border-box;

}

.gtr-container-p9q8r7 p {

font-size: 14px;

margin-bottom: 1em;

text-align: left !important;

}

.gtr-container-p9q8r7 strong {

font-weight: bold;

color: #0056b3;

}

.gtr-container-p9q8r7 a {

color: #007bff;

text-decoration: none;

}

.gtr-container-p9q8r7 a:hover {

text-decoration: underline;

}

.gtr-container-p9q8r7 .gtr-title-main {

font-size: 18px;

font-weight: bold;

margin-bottom: 1em;

color: #003366;

text-align: left;

}

.gtr-container-p9q8r7 .gtr-title-section {

font-size: 18px;

font-weight: bold;

margin-top: 1.5em;

margin-bottom: 1em;

color: #0056b3;

text-align: left;

}

.gtr-container-p9q8r7 .gtr-title-subsection {

font-size: 14px;

font-weight: bold;

margin-top: 1.2em;

margin-bottom: 0.8em;

color: #0056b3;

text-align: left;

}

.gtr-container-p9q8r7 .gtr-divider {

border: none;

border-top: 1px solid #eee;

margin: 2em 0;

}

.gtr-container-p9q8r7 ul,

.gtr-container-p9q8r7 ol {

margin: 0 0 1em 0;

padding: 0;

list-style: none !important;

}

.gtr-container-p9q8r7 ul li {

position: relative;

padding-left: 20px;

margin-bottom: 0.5em;

font-size: 14px;

text-align: left !important;

list-style: none !important;

}

.gtr-container-p9q8r7 ul li::before {

content: "•" !important;

position: absolute !important;

left: 0 !important;

color: #0056b3;

font-size: 1.2em;

line-height: 1;

}

.gtr-container-p9q8r7 ol {

counter-reset: list-item;

}

.gtr-container-p9q8r7 ol li {

position: relative;

padding-left: 25px;

margin-bottom: 0.8em;

font-size: 14px;

text-align: left !important;

list-style: none !important;

}

.gtr-container-p9q8r7 ol li::before {

content: counter(list-item) "." !important;

counter-increment: none;

position: absolute !important;

left: 0 !important;

color: #0056b3;

font-weight: bold;

width: 20px;

text-align: right;

}

.gtr-container-p9q8r7 .gtr-contact-name {

font-size: 14px;

font-weight: bold;

margin-top: 2em;

margin-bottom: 0.5em;

color: #003366;

text-align: left;

}

.gtr-container-p9q8r7 .gtr-contact-info-row {

display: flex;

flex-wrap: wrap;

margin-bottom: 8px;

font-size: 14px;

text-align: left;

}

.gtr-container-p9q8r7 .gtr-contact-label {

flex-shrink: 0;

width: 80px;

font-weight: bold;

color: #555;

text-transform: capitalize;

}

.gtr-container-p9q8r7 .gtr-contact-value {

flex-grow: 1;

min-width: 150px;

word-break: break-word;

color: #333;

}

@media (min-width: 768px) {

.gtr-container-p9q8r7 {

padding: 24px 32px;

}

.gtr-container-p9q8r7 .gtr-title-main {

font-size: 24px;

}

.gtr-container-p9q8r7 .gtr-title-section {

font-size: 20px;

}

.gtr-container-p9q8r7 .gtr-title-subsection {

font-size: 16px;

}

.gtr-container-p9q8r7 .gtr-contact-label {

width: 120px;

}

.gtr-container-p9q8r7 .gtr-contact-value {

min-width: 200px;

}

}

یک راکتور شیشه ای چیست و چگونه کار می کند؟

مقدمه

در آزمایشگاه های شیمیایی و تاسیسات تولید در مقیاس آزمایشی، کنترل دقیق شرایط واکنش بسیار مهم است. دمای، فشار و دید واکنش به طور مستقیم بر کیفیت محصول تاثیر می گذارد.ایمنی، و قابل تکرار است.راکتور شیشه ایبه یک قطعه ضروری از تجهیزات در کاربردهای شیمیایی، داروسازی و تحقیقاتی تبدیل شده است.

یک راکتور شیشه ای پوشش داده شده به طور خاص برای انتقال گرمای کارآمد طراحی شده است و در عین حال به اپراتورها اجازه می دهد تا واکنش های شیمیایی را به صورت بصری در زمان واقعی نظارت کنند.یک راکتور شیشه ای چیست؟,چطور کار ميکنهوچرا در پردازش شیمیایی مدرن به طور گسترده استفاده می شود.

یک راکتور شیشه ای چیست؟

یک راکتور شیشه ای پوشاندهراکتور شیشۀ شیمیاییساخته شده از شیشه بوروسیلیکات بالا و مجهز به یکساختار دو لایه ایظرف داخلی مواد واکنش را نگه می دارد، در حالی که ژاکت بیرونی اجازه می دهد رسانه های گرمایش یا خنک کننده مانند آب، روغن یا گلیکول در اطراف اتاق واکنش گردش کنند.

این طراحی امکان کنترل دقیق دمای بدون تماس مستقیم بین محیط گرمایش و مخلوط واکنش را فراهم می کند.راکتورهای شیشه ای دارای پوشش به طور قابل توجهی ثبات حرارتی و ایمنی را بهبود می بخشند..

یک راکتور شیشه ای چگونه کار می کند؟

اصل کار یک راکتور شیشه ای بسته بر این اساس استانتقال گرمای غیر مستقیم:

فرآیند واکنشمواد خام در ظرف شیشه ای داخلی بارگذاری می شوند، جایی که واکنش های شیمیایی مانند سنتز، مخلوط کردن، بلوری یا تقطیر رخ می دهد.

کنترل دمایک واحد کنترل دما مایع گرمایشی یا خنک کننده را از طریق ژاکت بیرونی گردش می کند. گرما به طور مساوی از طریق دیواره شیشه ی بوروسیلیکات منتقل می شود و دمای واکنش پایدار را تضمین می کند.

سیستم تکان دادنیک مخلوط کننده مکانیکی به طور مداوم مواد واکنش را مخلوط می کند تا توزیع گرما و کارایی واکنش را بهبود بخشد.

کار با خلاء یا فشاربسته به کاربرد، راکتور می تواند تحت خلاء یا فشار کمی کار کند تا شرایط واکنش را بهینه کند و نقاط جوش را کاهش دهد.

این ترکیب گرمایش کنترل شده، مخلوط کردن یکنواخت و خلاء اختیاری باعث می شود که راکتورهای شیشه ای جاکت شده برای فرآیندهای شیمیایی حساس ایده آل باشند.

مزایای اصلی راکتورهای شیشه ای

کنترل دقیق دما

ساختار ژاکت شده انتقال گرما را یکنواخت تضمین می کند و نوسانات دمایی را که می تواند بر نتایج واکنش تأثیر منفی بگذارد به حداقل می رساند.

مقاومت شیمیایی عالی

شیشه بوروسیلیکات بالا در برابر خوردگی از اسید ها، قلیات و حلال های آلی مقاومت دارد، که آن را برای طیف گسترده ای از واکنش های شیمیایی مناسب می کند.

دید کامل واکنش

ظرف شیشه ای شفاف به اپراتورها اجازه می دهد تا تغییرات رنگ، بلوری یا جدایی فاز را در طول واکنش به صورت بصری نظارت کنند.

امنیت بیشتر

گرم کردن غیرمستقیم خطر گرم شدن بیش از حد محلی را کاهش می دهد، در حالی که سازگاری خلاء ایمنی را در طول واکنش های تنفسی بهبود می بخشد.

کاربردهای معمول

راکتورهای شیشه ای پوشه شده به طور گسترده ای در:

تحقیقات داروسازی و توسعه API

سنتز شیمیایی خوب

آزمایشگاه های دانشگاهی و نهادی

آزمایش های شیمیایی در مقیاس آزمایشی

تحقیقات در زمینه لوازم آرایشی و افزودنی های غذایی

انعطاف پذیری آنها باعث می شود که آنها هم برای تحقیق و توسعه و هم برای تولید دسته کوچک مناسب باشند.

راکتور شیشه ای جاکت شده در مقابل راکتور تک جاکت

در مقایسه با ظروف یک یا بدون ژاکت، راکتورهای شیشه ای ژاکت ارائه می دهند:

کنترل دمای پایدارتر

بهره وری بهتر انتقال گرما

ثبات واکنش بالاتر

امنیت عملیاتی بیشتر

برای فرایندهایی که نیاز به تحمل شدید دمایی دارند، طراحی ژاکت اغلب انتخاب ترجیحی است.

نتیجه گیری

یک راکتور شیشه ای با ژاکت یک راه حل قابل اعتماد، متنوع و امن برای پردازش شیمیایی مدرن است. توانایی آن برای کنترل دقیق دمای، مقاومت شیمیایی عالی،و دید کامل فرآیند آن را در آزمایشگاه و برنامه های کاربردی در مقیاس آزمایشی ضروری می کند.

اگه دنبال يهرآکتور شیشه ای بسته شده سفارشیبا عملکرد قابل اعتماد و پشتیبانی فنی حرفه ای، کار مستقیم با یک تولید کننده با تجربه می تواند به طور قابل توجهی کارایی پروژه شما را بهبود بخشد.

مشاهده بیشتر